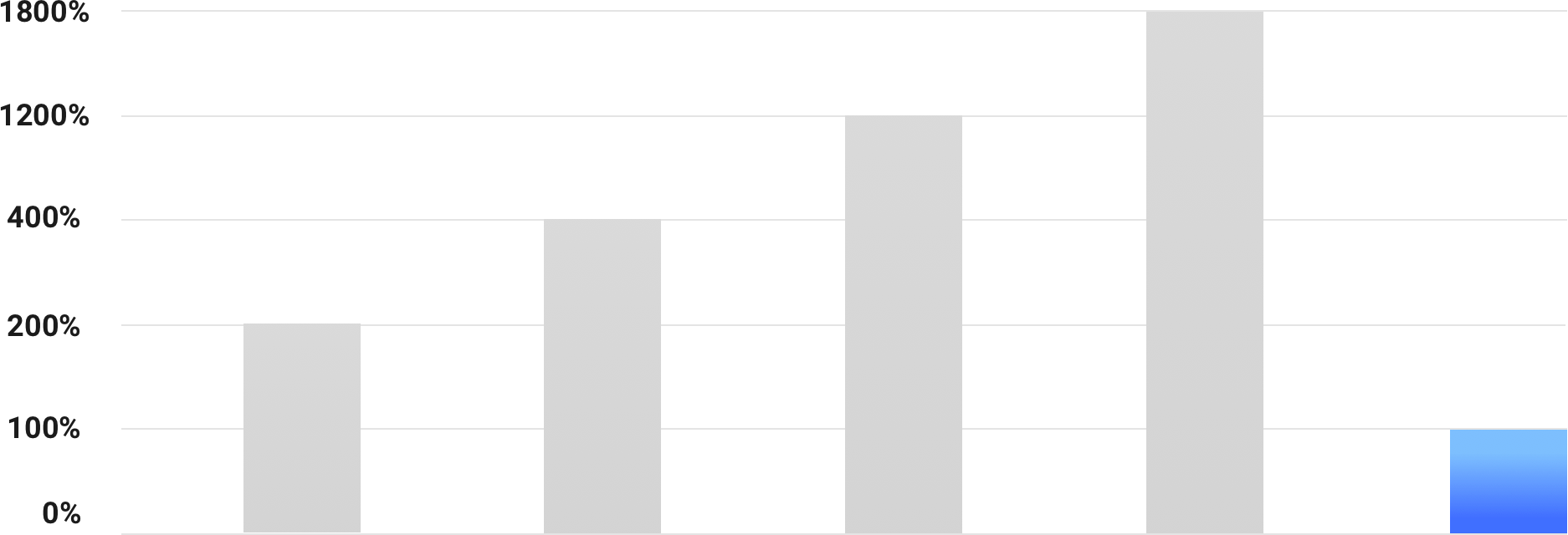

String technology outperforms all modes of transport

Eco-friendliness

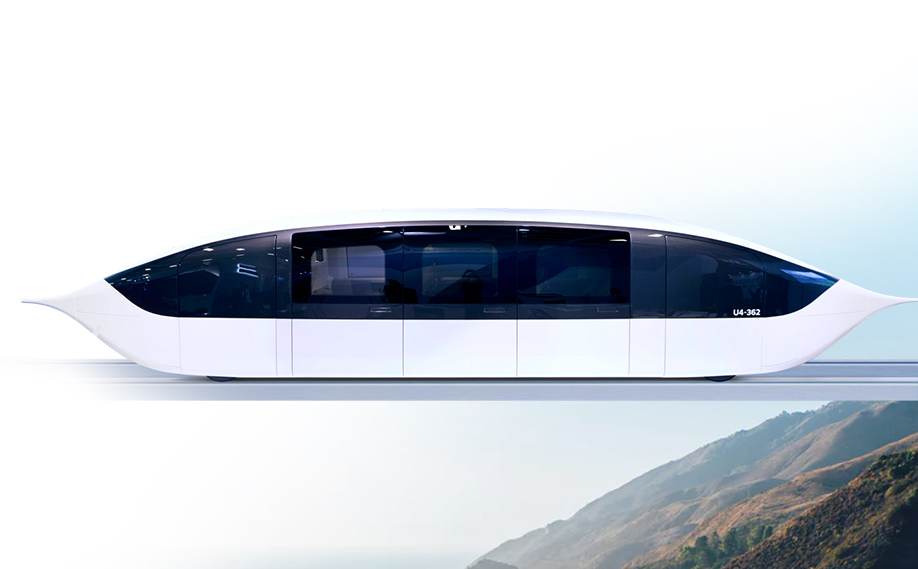

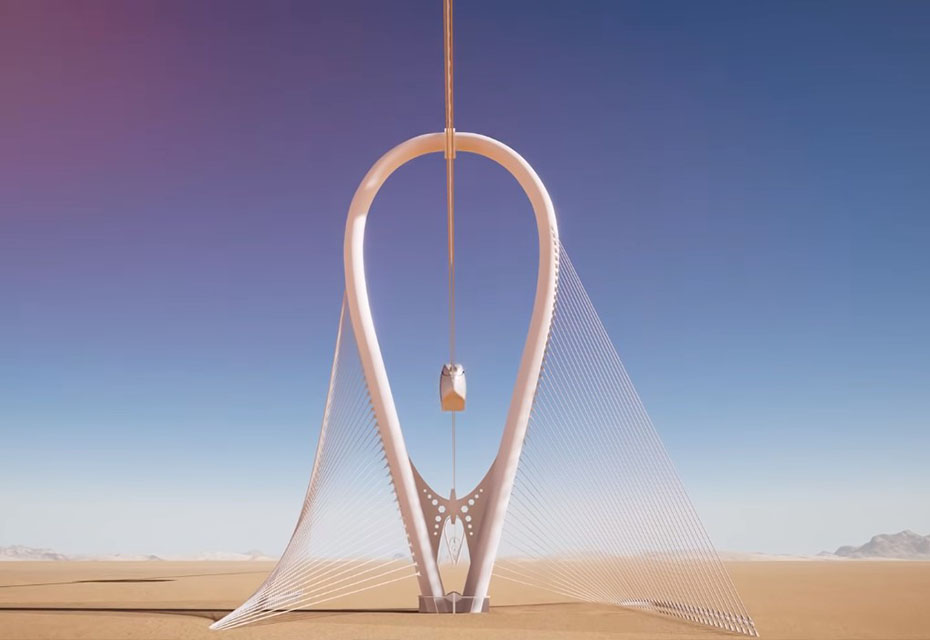

- String tracks take up a minimum of space on the ground — this helps to keep the natural ecosystem and biogeocenose intact.

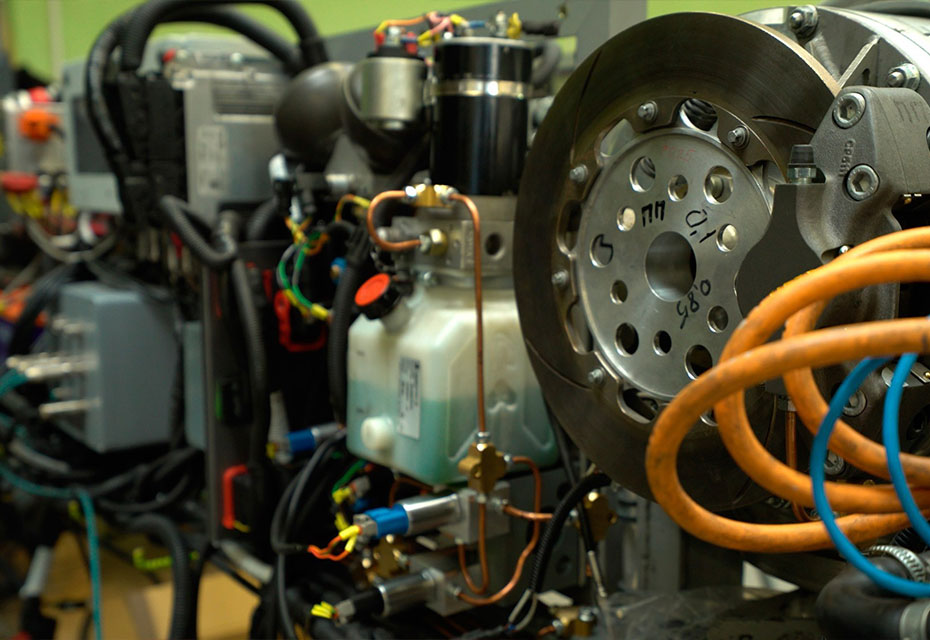

- String transport runs on electricity and therefore significantly reduces harmful emissions into the atmosphere.

- String transport infrastructure requires far less materials and raw materials to produce than any other transport infrastructure.

Economy

- The cost of erecting string tracks is up to 20 times lower than that of any other mode of transport.

- Fuel costs are up to 6 times lower than those of other modes of transport, and accordingly, the cost of travel and transport is also lower.

- String tracks can be built in any region with any climate: large metropolis, forest, water bodies, swamps and deserts.

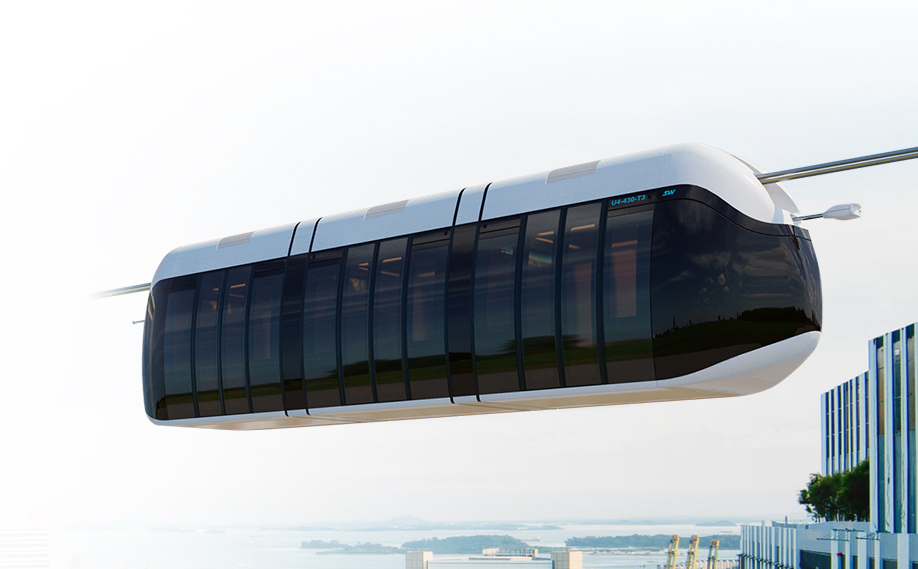

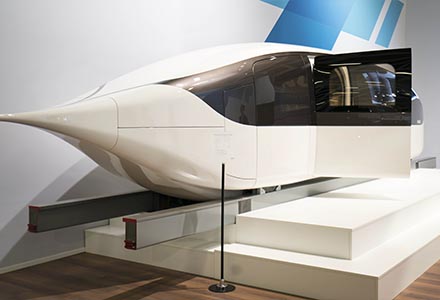

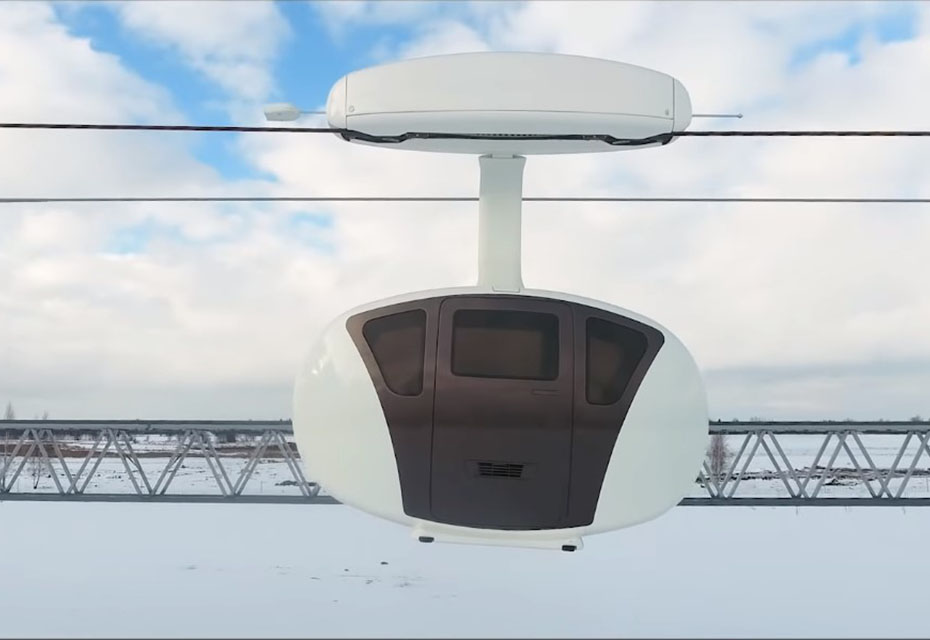

Speed

- High-speed string transport can reach speeds of up to 500 km/h — twice as fast as Russia's fastest train, the Sapsan.

- Urban string transport can reach speeds of up to 150 km/h — that's twice as fast as buses.

- Freight string transport can reach speeds of up to 150 km/h.

Safety

- The track structure is located above the ground and increases safety by about 100 times.

- The anti-derailment system increases safety by a further 10 times.

- High resistance to terrorism and vandalism.

- Automated control system eliminates the human factor

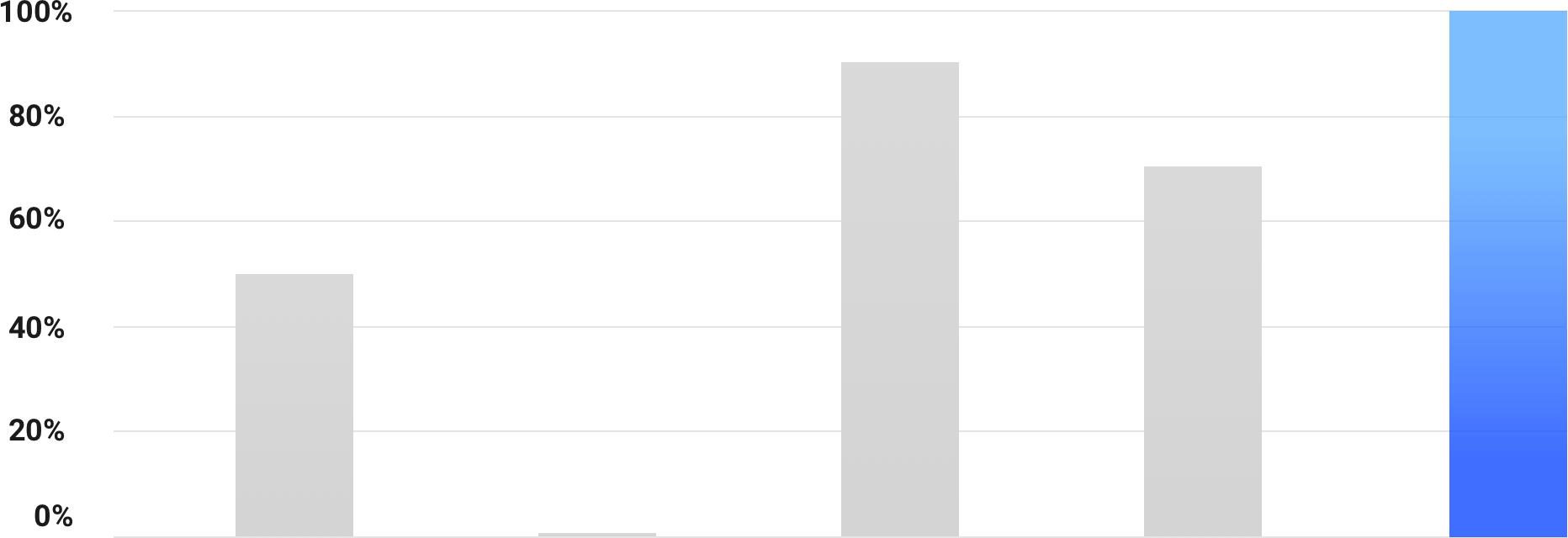

cost

safety

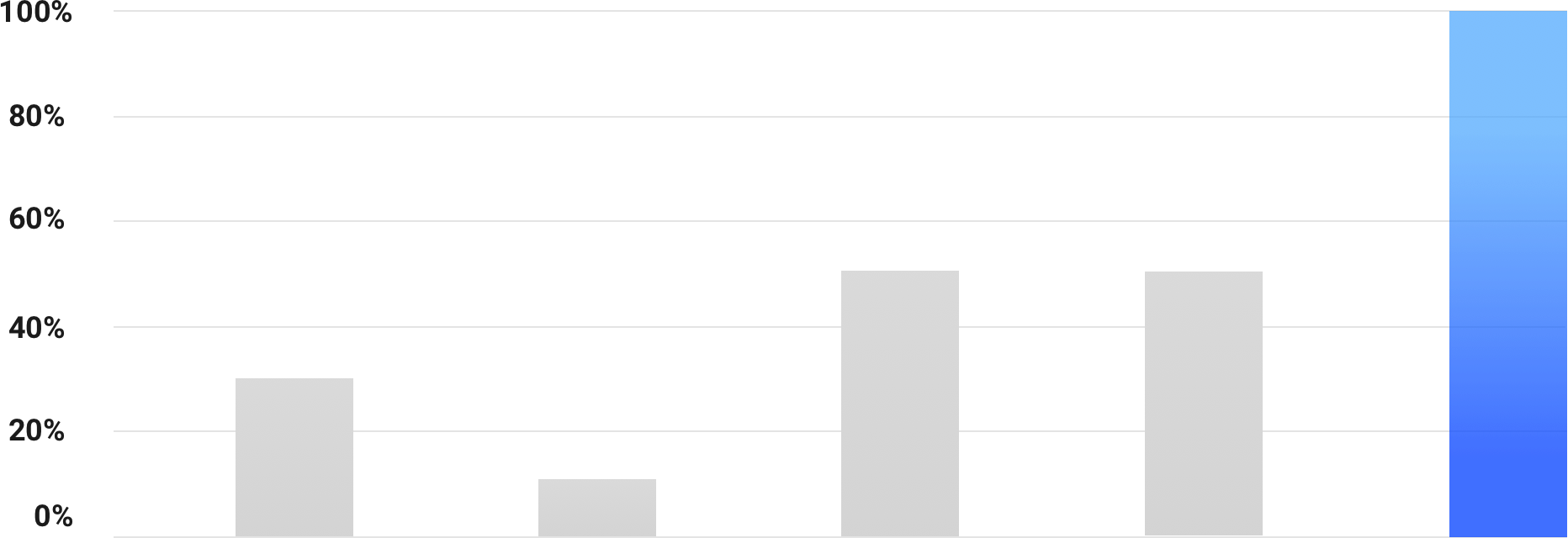

eco-friendliness

Railway transport

Road transport

Monorail

Maglev

SkyWay

Railway transport

Road transport

Monorail

Maglev

SkyWay

Railway transport

Road transport

Monorail

Maglev

SkyWay

The data are based on a study by the Institute of Transport Problems n.a. N.S. Solomenko of the Russian Academy of Sciences, as a percentage of the integral indicator by mode of transport.